How AI Driving Transformation In Oil And Gas Industry

Quick Summary: Let’s have a look at how AI Driving Transformation in the Oil and Gas Industry! Are you curious to know? If yes then let’s read this article… AI is revolutionizing the oil and gas industry by streamliningAI upstream oil operations

Introduction

In technological evolution, artificial intelligence (AI) remains a transformative force, reshaping industries everywhere. One such industry undergoing significant change is the oil and gas industry. The benefits of AI for the Oil and gas sector are unparalleled.

The digital oil and gas solutions have the ability to analyze big data, predict outcomes and optimize operations, and have become a cornerstone of innovation in this industry.

Gone are the days of relying solely on human knowledge and craftsmanship. Today, AI-powered systems enhance exploration energy production processes, transform mining operations, and streamline manufacturing processes made available by AI combined with IoT (Internet of Things) technologies and big data analytics unprecedented insights. It enables businesses to make data-driven decisions faster and with greater accuracy.

Read more about this revolutionary transformation in oil and natural gas operations that has occurred due to AI!

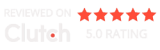

Overview To artificial intelligence oil and gas Software

AI in oil and gas industry transforming its operations by modifying software programs designed to meet specific needs. AI-driven software in oil and gas help in this area will play a key role in increasing operational efficiency. It reduces costs and optimizes decision-making processes.

One of the most important AI features in oil and gas software is predictive maintenance. By analyzing large amounts of data from sensors, computer systems and devices, AI algorithms can predict potential device failures in advance. This proactive approach reduces downtime, improves safety, and significantly reduces maintenance costs.

Additionally, AI algorithms help optimize drilling operations. They analyze geological data to determine the best drilling locations. It automatically predicts reservoir characteristics, and optimizes mining operations for efficiency and production efficiency.

Additionally, AI-powered software enables advanced data analysis for pond characteristics and product optimization. By processing seismic data, well logs, and production data, AI algorithms provide valuable insights into reservoir behavior. It processes, and potential upgrade opportunities.

How Much Is AI Beneficial for oil and gas Companies?

Artificial intelligence (AI) offers significant benefits to oil and gas companies in various business segments. This makes it a valuable technology in the industry. First, AI predictive maintenance helps detect device failures early. It reduces AI downstream processes and optimizes maintenance planning. Thus, it enables AI algorithms to analyze seismic data and well data for analysis accuracy. This gives a better indication of the characteristics of the reservoirs and greater success in dredging operations. It helps predict equipment failure.

Additionally, AI increases productivity by streamlining operations and processes. It reduces waste and increases productivity. Additionally, playing a key role in security and risk management through real-time analysis and early AI oil spill detection of potential anomalies or threats. AI-powered analytics and machine learning algorithms enable better decision-making through deliverable insights derived from large amounts of data. It also improves the overall performance of ai systems. It keeps historical maintenance records.

Moreover, AI-powered automation simplifies routine tasks, such as data entry and analysis, freeing up human resources for more strategic useful activities. Overall, AI integration in oil and gas companies increases efficiency. It reduces operating costs. It improves safety measures and allows for better route decisions. Very useful for the growth and sustainable development of the industry.

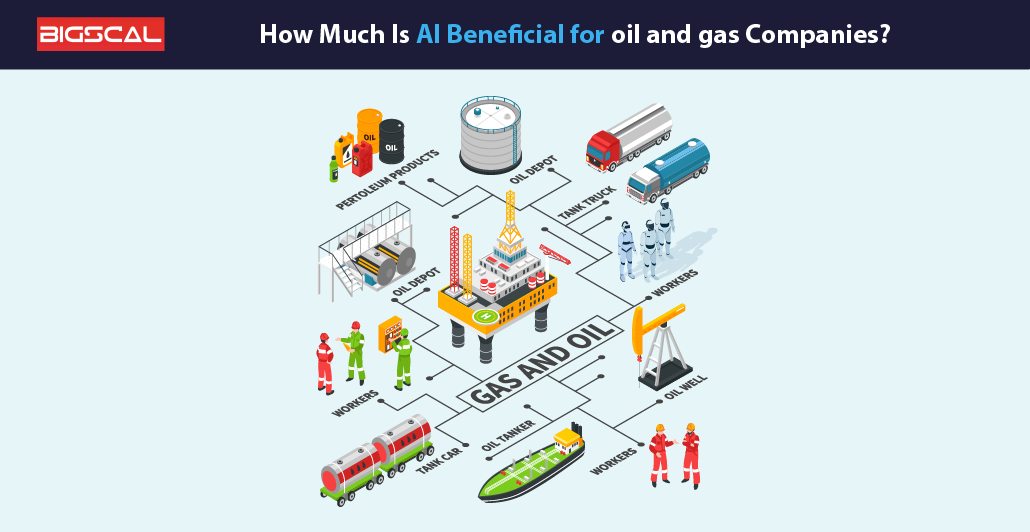

In What Ways is AI Driving Transformation in the Oil and Gas Industry?

Check out how oil and gas software companies are creating digital transformation in oil and gas industry or how AI Driving Transformation in Oil and Gas Industry:

Predictive Maintenance Models

AI-powered predictive maintenance models have revolutionized operations in the oil and gas industry. By using machine and deep learning models and algorithms to predict equipment failures before this approach reduces downtime. It reduces maintenance costs and increases overall operational efficiency.

By analyzing historical data, sensor readings, and machine performance metrics, AI algorithms can identify patterns and anomalies analyzing data that indicate potential problems. This enables companies to schedule maintenance activities during planned downtime projects, avoiding costly unscheduled time.

Furthermore, AI-powered predictive maintenance enables the implementation of condition-based maintenance methods for critical infrastructure. Sensors embedded in critical equipment continuously collect real-time data, which is then analyzed by AI algorithms to detect early signs of damage or malfunction. This approach to quality AI safety monitoring oil prevents catastrophic failures, extends machine life and improves workplace safety.

Oil and Gas Exploration and Production

AI technology leading to significant improvements in efficiency, cost savings and environmental sustainability. In exploration, AI in oil and gas processes provides a wealth of geological and seismic data to pinpoint potential mine locations with precision and accuracy. This reduces exploration risks and improves the chances of discovering potential reserves well. In addition, AI-driven predictive analytics help optimize reservoir management by predicting production, optimizing well spacing, and improving recovery rates.

During development, AI plays a key role in optimizing drilling and completion plans, mining operations and dam performance. Artificial intelligence drilling automation systems equipped with AI algorithms can adjust drilling parameters in real time, improving drilling parameters, reducing costs. It also reduces environmental impact and what’s more, AI-driven production optimization models to identify opportunities for process improvement. And it analyzes manufacturing data to reduce downtime and optimize resources.

supply chain management

AI is revolutionizing supply chain management in the Oil and gas digitalization, by increasing operational efficiency, reducing costs, and improving decision-making processes. One key area where AI is having a significant impact is maintenance delivery and predicting where training data is the answer. By analyzing historical data and real-time sensor data, AI algorithms can predict machine failures and maintenance needs. Thereby reducing downtime and optimizing asset utilization.

Additionally, AI-powered algorithms are used to predict demand, helping companies optimize inventory and streamline the purchasing process. AI also plays a key role in supply chain optimization. It optimizes logistics by analyzing various factors such as transportation routes, weather conditions and oil and gas industry market demand. It is to reduce transportation costs and improve supply chain efficiency.

Furthermore, AI-driven automation makes order processing, inventory management demand forecasting, and invoicing more accurate and faster. It leads to faster and more efficient supply chain operations. Overall, AI in supply chain management for oil and gas companies can achieve greater operational speed, affect efficiency and sustainability.

Reservoir Management

AI is revolutionizing reservoir management in the oil and gas industry by leveraging advanced analytics, machine learning and big data technologies. One of the major applications of AI oil reservoir management is reservoir modeling and simulation. AI algorithms analyze vast amounts of soil and geological data to create more accurate reservoir models, predict reservoir behavior and optimize production.

AI-driven predictive analytics play an important role in reservoir performance management and optimization. By continuously analyzing production data, well performance and reservoir status, AI algorithms can identify oil and gas industry technology trends, anomalies and optimization opportunities in real time, enabling operators to make data-driven delivery decisions productivity has increased and costs have been reduced.

In addition, AI-powered predictive maintenance helps prevent equipment failures and downtime in pool operations, and ensures smooth processing and efficiency. AI facilitates advanced data drives together and reviewed. It allows reservoir engineers to gain deeper insights into reservoir dynamics and make informed decisions to optimize production with the Digital workflow oil industry.

Inventory Management

Artificial intelligence (AI) is revolutionizing inventory management in the oil and gas industry through the introduction of predictive analytics and advanced optimization techniques. The most important mechanisms through which AI drives this transformation. One of the benefits is predictive maintenance. By analyzing historical data and real-time sensor data from devices and pipelines, AI algorithms can predict device failures. With that it can recommend preventive maintenance, thereby reducing downtime and operating costs.

In addition, AI-powered inventory management systems use machine learning algorithms to optimize inventory levels. This model makes accurate demand forecasts by analyzing consumption patterns, market trends and supply chain data. This capability allows companies to maintain optimal stock levels. It reduces excess inventory and avoids shortages. It ultimately improves efficiency and reduces storage costs.

Another area where AI makes a difference is AI supply chain optimization. AI algorithms can optimize transportation routes, optimize delivery schedules, and identify potential bottlenecks in the supply chain. It leads to cost savings and streamlined operations.

Carbon Emissions Reduction

AI is playing an important role in helping the oil and gas industry meet environmental challenges, especially in reducing carbon emissions. It helps in AI energy consumption reduction. One of the key ways AI can support this effort is through advanced data analytics and modeling. AI algorithms analyze a wealth of oil and gas industry information including emissions data. Manufacturing processes and the environment to identify opportunities to reduce emissions.

AI-powered predictive modeling helps companies optimize their operations to reduce greenhouse gas emissions. By simulating various scenarios and controlling processes such as mining, extraction, recycling and distribution, AI can enforce environmentally friendly practices.

Furthermore, AI plays an important role in improving energy efficiency. AI algorithms can analyze energy usage, detect inefficiencies, and recommend energy-saving measures. In addition, AI-enabled monitoring and monitoring systems continuously monitor emissions in real time to quickly detect abnormalities or exceed oil and gas industry regulations limits. This approach helps companies take immediate corrective action to reduce environmental impact.

Natural Language Understanding

Natural Language Understanding (NLU) in AI has revolutionized the oil and gas industry by enhancing the decision-making process. It allows them to sift through large amounts of unstructured data from sources such as oil and gas industry reports, emails, and maintenance logs, and gain valuable insights. It can translate complex technical jargon of the NLU process, strengthen communication between teams, and facilitate knowledge sharing.

In addition, NLU-powered AI systems are capable of executing automated business processes. This business process includes contract analysis and compliance monitoring. Understanding nuances of language to streamline operations and reduce human error and support these processes in risk assessment. Compliance and anomaly detection, proving efficiency across the industry and making the decision.

Remote Monitoring

A.I. AI algorithms can detect anomalies, predict machine failures and optimize production processes. This improves operational efficiency and cost savings.

Additionally, AI-powered remote sensing techniques enhance security by identifying potential threats and enabling proactive security measures. They enable remote device control and management, reduce the need for on-site personnel, and minimize downtime.

Moreover, AI-powered remote monitoring is driving a digital transformation in the oil and gas industry. Through actionable insights, operational efficiencies and safety and sustainability regularly improving the quality.

Energy Efficiency

AI is revolutionizing the oil and gas industry by increasing energy efficiency. Advanced AI algorithms are being used to optimize processes such as drilling, extraction and transportation, reducing energy consumption and costs. Machine learning models analyze large amounts of data from sensors. Weather forecasts and historical metrics to predict device failures, prevent downtime and improve overall operational efficiency.

Additionally, AI-powered predictive maintenance systems identify anomalies and suggest maintenance schedules. It is to prevent costly machine breakdowns and reduce energy consumption. This approach allows companies to reduce when they are used to increasing productivity. It improves asset utilization and ultimately achieves greater energy savings.

supervised learning techniques

Supervised learning techniques play an important role in the Digital oilfield transformation. It enables accurate data analysis and decision-making. Through supervised learning, AI systems are being trained on large datasets to identify patterns, anomalies and trends in various areas such as reservoir characterization, production optimization and risk management.

These techniques facilitate predictive models for reservoir simulations. It helps companies forecast production rates, optimize well placement, and make informed investment decisions. Furthermore, curriculum observation analyzes real-time data from sensors to identify potential hazards or operational changes. It also ensure safety measures are adhered to Reduces risks and enhances safety measures throughout operations.

Take Bigscal Technologies Help To Integrate AI In Your Oil and Gas Businesses?

Bigscal Technologies provides comprehensive AI integration solutions specifically designed for the oil and gas industry. Utilizing state-of-the-art AI technology, they offer a range of services aimed at improving efficiency and decision-making.

Our AI solutions can process real-time data from a variety of sources, including sensors, drones, and satellite imagery. It enables forecasting, resource optimization and risk management solutions. Additionally, their AI systems can automate routine tasks, streamline business processes. It also pinpoints patterns and anomalies overlooked by human operators. Not only does this reduce operating costs not only but also increases safety and reliability throughout the value chain.

Partnering with Bigscal Technologies will allow oil and gas companies to harness the power of AI to drive innovation, improve efficiency and compete in today’s dynamic marketplace.

Conclusion

There is no doubt that AI is driving profound changes in the oil and gas industry. It transforms operations, increasing safety and improving efficiency through its ability to analyze vast amounts of data in real time. The continued integration of AI in the oil and gas industry represents a shift towards a smarter, more efficient and transformative future.

FAQ

What is minimal human intervention?

Minimal involvement refers to a process or system that operates with few hands. It relies heavily on automation, algorithms, or self-regulating processes to operate efficiently and effectively.

Which oil and gas companies are using AI?

Major oil and gas companies such as ExxonMobil, Shell, BP, Chevron and Total are aggressively using artificial intelligence technologies in their operations. It includes exploration, production and refining.

What is C3 oil and gas?

C3 AI, commonly referred to as C3, is a software company that specializes in enterprise AI applications. It provides AI solutions for various industries, including oil and gas, to streamline operations and improve decision-making processes.

How is AI used in the oil industry?

AI is used in the oil industry for:

- predictive equipment maintenance

- reservoir modeling,

- drilling optimization,

- production forecasting,

- safety management and decision support

What is the application of ML in oil and gas?

Machine learning (ML) is being applied to oil and gas for:

- reservoir characterization

- predictive maintenance

- anomaly detection

- production optimization

- seismic interpretation

- risk analysis to improve exploration

- production and operational efficiency