Benefits of Artificial Intelligence In Supply Chain and Logistic

Quick Summary: AI is transforming every industry including supply chains and logistics. artificial intelligence in supply chain industry transforming in every way possible. It provides benefits in various ways. Which includes increasing productivity, reducing costs and improving decision making. AI-powered predictive analytics optimize inventory management, reducing inventory and overstock. Machine learning algorithms streamline the learning process. It results in faster delivery and reduced fuel consumption. Know more benefits by reading this article!

Introduction

Artificial intelligence is revolutionizing the logistics business processes. Artificial intelligence in supply chain delivers an array of benefits that drive business efficiency and success. In today’s fiercely competitive global marketplace, organizations are constantly looking for innovative solutions to streamline their operations. It reduces costs and increase customer satisfaction. Additionally, AI is emerging as a best solution for all modern issues.

But what exactly are these benefits?

One of the key benefits of integrating AI into the supply chain and logistics is its ability to optimize processes and improve decision-making. Through advance algorithms and machine learning, AI systems can analyze large amounts of data in real time. It can identify patterns, predict demand, and optimize inventory levels with unparalleled accuracy. This predictive capability reduces inventory cost overruns. It ensures on-time delivery, thereby improving overall operational efficiency. It reduces supply chain disruptions.

Furthermore, AI-driven automation plays an important role in increasing productivity and reducing human error. Activities such as strategic efficiency, demand forecasting and warehouse management can be streamlined. This allows employees to focus on higher-value activities that require creative and strategic thinking. This not only increases productivity but also reduces costs and improves customer service.

Wanna know more about this?

Then read this article and understand why you must use a logistics software development company to use AI into your supply chain operations.

Overview To AI in Supply Chain Management

Artificial intelligence in supply chain management is an effective approach to improve overall efficiency. It increases productivity, reduces costs and optimizes processes. AI in SCM affects various technologies. These technologies include machine learning, predictive analytics, natural language processing and robotics. Additionally, it enhances supply chain processes and even global supply chains.

One of the most important applications of AI for supply chain companies is demand forecasting. Machine learning algorithms analyze historical data, market data and external factors to determine exact requirements. Thus, it reduces stockout and overstock situations. It leads to better inventory management and cost reduction.

Supply chain automation company offer predictive maintenance. It ensures the optimal performance of machinery and equipment by analyzing data from sensors. It anticipates maintenance needs before failure. Hence, this prevents downtime, reduces maintenance costs and extends asset life.

The role of generative ai optimize algorithms in AI analyze routes, optimize logistics scheduling, and simplify logistics and transportation by reducing fuel consumption. This improves delivery times, reduces transportation costs and increases customer satisfaction.

AI-powered supply chain visibility provides real-time insights into inventory levels, shipment status and potential problems. It enables decision-making and risk management for supply chain partners.

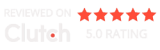

AI Use Cases In Supply Chain Management

Before understanding the benefits of AI for supply chain managers, let’s have a look at its use cases:

Customer Care Services

AI enhances customer service operations through chatbots and virtual assistants that provide 24/7 support, solve queries more efficiently and reduce response times. Natural Language Processing (NLP) enables these AI systems to better understand and answer customer queries, improving overall customer satisfaction.

Sentiment analytics algorithms measure consumer sentiment by analyzing customer feedback and social media data, enabling companies to identify areas for improvement, rapidly process information with AI-driven personalized recommendations and tailored product suggestions based on purchase history and preferences. Therefore, overall Customer experience is improved.

Inventory Management

AI is playing an important role in optimizing inventory management by accurately predicting demand using advanced algorithms. It analyzes historical data, market data, and external sources to forecast inventory needs, and minimizes overstocking of inventory shortages.

The AI-powered inventory management system can automate replenishment processes. Dynamically change security stock levels, and identify slow moving or expired items for better inventory control.

Vendor Management

AI enhances vendor management by streamlining communications, analyzing supplier performance, and identifying potential risks. It performs routine tasks such as order placement, invoicing, and performance reviews, and automates the resources to build strategic vendor relationships.

AI-driven analytics provide insights into vendor reliability, quality consistency, and price competitiveness. It enables organizations to make data-driven decisions to select and manage vendors effectively.

Value Chain Analysis

AI contributes to the analysis of the current situation by creating a value stream that links together the various data sources. On the other hand, it is to ascertain whether we can make any reductions, improvements or pricing adjustments.

Takes machines learning to uncover patterns, predict results and distribution of resources, to collect goals. Ai embedding in the organization can savor a lot for an organization by increased efficiency, enhanced ability to adapt and to respond better to the market trends.

Human Resource Management

AI has become really prominent in HR management through the activities of automating recruitment processes like screening of resumes, scheduling interviews and onboarding new employees. AI-driven talent acquisition platforms leverage data mining to spot a high potential employee plus right the size of the workforce in business cycles and costs.

With the help of AI tools, organizations analyze employee sentiment, collect data and evaluate the dynamics of employee morale, and also develop a kind organization involving employee engagement. AI which supports learning and development provides a training system which is adapted to individual learners’ style and personnel and respective performance to increase employees’ skills level and productivity.

Warehouse Management

AI transforms warehousing through optimizing included functions like inventory management, inventory optimization and the accuracy of orders. AI-powered predictive maintenance use capabilities of AI in detecting equipment’s health status in real-time, finding problems at a point that is not an issue yet and hence brings down downtime.

Through AI-powered forecasting and inventory optimization algorithms, we can help retailers better plan for the future. It aims at the same maximum stock capacity. In addition, it accomplishes both significant supply chain benefits of inventory cost reductions while ensuring the provision of customer service levels.

Read more: A Comprehensive Guide To Logistics App Development

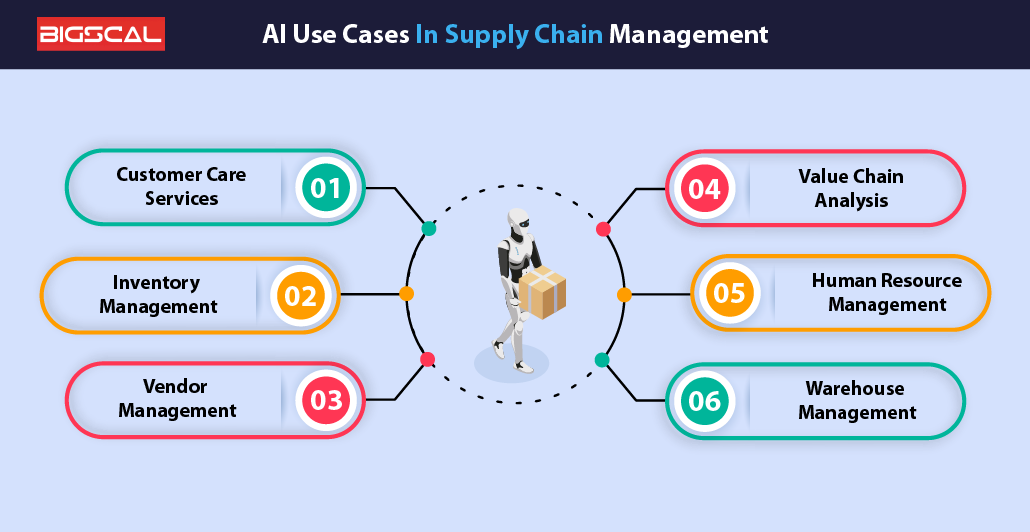

The List Of Benefits Of Integration Of AI in Supply Chain And Logistics

Here’s the list of top benefits of integrating AI in Supply Chain And Logistics:

Optimized Operations

AI becomes a part of supplier and logistics control, cutting down some life-wasting processes. The System will make the operations of the chain from beginning till end. For instance, AI technologies powered by machine learning algorithms permit examining multiple pieces of data and having this data be assessed for understanding patterns, trends and discrepancies during all time periods. That enables the enterprise to do synthetic intelligence with information. It enhances the forecasting precision, and also helps in achieving desired inventory quality.

The major advantages are that it will enable automation of repetitive labors such as purchasing, inventory and production management processes. AI systems are capable of automating tedious jobs, smart resource management, and cost reduction in organization’s operations. For instance, delivery of the last mile for which can be accomplished by means of autonomous vehicles and drones can be made quicker with faster delivery and less human errors.

Furthermore, AI brings an extra layer of visibility in the supply chain mainly by way of real-time tracking and monitoring throughout the supply process. Such transparency facilitates identifying and solving issues with greater efficiency, quicker problem solving and satisfied customers. In a nutshell, AI integration into operations is the only way to achieve the society of tomorrow thus improving productivity levels. It managed the reduced downtime and utilization through resources.

Efficient Supply Management

Artificial intelligence is playing a very significant role in transforming supply chain management. It speeds up predictive analytics, demand forecasting, and intelligent inventory management. Through examination of the historical data, market tendencies and external factors, the AI algorithms can predict future demand patterns precisely. It regulate inventory levels based on the demand which in turn leads to customer satisfaction that reduces the instances of warehouse surpluses and wastage.

Furthermore, artificial intelligence-driven supply management systems are able to automate procurement processes. As it prioritizing for suppliers, contract negotiation and managing supply relationships. Thereby increasing efficiency and reducing costs and improvement of the supplier performance as well as flexibility of supply chain.

Moreover, AI provides visibility across all the supply chain which partners suppliers, manufacturer companies, distributors and shops. Via this transparency it becomes possible to apply better collaborative schemes, risk mitigation and making decisions which need to be taken timely. Consequently, supply chains which are controlled by AI help bring down expenses, produce flexibility as well as gaining winning and advantageous market share.

Enhanced Predictive Analytics

We also gather our data regarding the upcoming operational shifts through AI-powered predictive analytics that are thought provoking and actionable. This oneshot was instrumental in narrowing down issues while improving decision making. With such generative AI development services in data analytics methods Artificial Intelligence algorithms have the capability to achieve forecasting demands, prediction of market trends, and optimized supply chain management through its directive.

The most advantageous thing about the trend toward predictive analytics is that there is now a higher level of accuracy in demand forecasting. Artificial intelligence can digest different sources of data to generate more precise continuance estimates; for example, it can process historical sales datums, customers” behavior, economic indicators, social network trends, and this will consequently help businesses to optimize inventory, resources and ultimately produce consumer requirements.

Improved Inventory Management

Integrating artificial intelligence in supply chain and the logistics process allows for largely inventory management improvements. AI-powered software could analyze the past data, the business trends that are currently in existence, and the market demand which will help to predict the sales in future with accuracy. This forecasting becomes useful in minimizing risks of having inventory losses or surplus quantities. It reduces the opportunity to overstocked while ensuring that there is enough stock to meet demand. It mitigate damage from stockouts, reduce price marked-downs, and possibly the out-of-stock.

As well, AI algorithm is able to garner actual decisions from real sources of data to support the normal operation of manufacturing, production, distribution and distribution. This final outcome contributes to the increase of the overall levels of inventory effectiveness. It avoids losses of the purchase orders and so does not lead to an increase in the production of non-consumable stocks.

Efficient Route Planning

AI based integration is not just revolutionising the way of route being designed in logistics field but also plays a key role. Implementing real-time data from traffic congestion to weather forecasts, delivery systems. AI algorithms can find best routes for delivery. So that included factors such as distance, time, fuel consumption and power capacity could be considered. It make delivery process efficient use of resources and reduce transportation costs.

Moreover, machine-learning technologies can provide an immediate solution of re-routing and real-time rescheduling in case of sudden traffic jams. This excitement enables delivery companies to increase speed and servicing reliability, so customer satisfaction rates go up. In such a manner, delivery companies provide competitive advantage in the market.

Optimize logistics operations

AI integration optimizes diverse elements of logistics operations, from warehouse control to reserve success. AI-driven technology like robotic manner automation (RPA), predictive analytics, and system gaining knowledge of algorithms. It enhance operational efficiency with the aid of automating recurring tasks. It optimizing workflows, and enhancing selection-making approaches.

For instance, AI-powered warehouse management structures can automate stock tracking, picking, packing, and shipping processes, lowering mistakes, minimizing exertions prices, and dashing up order achievement. Additionally, AI algorithms can analyze full-size quantities of information to become aware of traits, patterns, and opportunities for optimization across the entire logistics community, permitting continuous development and value discount.

Enhanced Customer Experience

Integrating artificial intelligence in supply chain and logistics enhances customer experience by streamlining processes and improving overall efficiency. One of the most important benefits is the ability to provide customers with real-time tracking and updates on their orders. AI-powered systems are able to predict delivery times more accurately, reducing uncertainty and allowing customers to plan accordingly. This transparency increases customer confidence and satisfaction.

Additionally, AI algorithms can analyze customer data and behavior to automate transactions. This includes relevant product recommendations based on products purchased or preferred, creating a more personalized shopping experience. This customization process not only increases customer satisfaction but also increases customer retention and loyalty.

Additionally, AI helps manage inventory, ensuring products arrive when customers need them. This reduces stockouts and backorders, further improving the overall experience. By leveraging AI technology, supply chain and logistics companies can better meet customer expectations, ultimately leading to higher levels of customer satisfaction and loyalty.

Supply Chain Visibility

Integrating AI enables increased supply chain visibility by providing both real-time insights and analytics across the supply chain. AI-powered systems can collect and analyze vast amounts of data from a variety of sources, including suppliers, warehouses, logistics and demand systems. This summary provides better visibility into the supply chain, identifying potential bottlenecks or inefficiencies.

Through AI algorithms, companies can accurately forecast demand, optimize inventory and reduce excess or shortages. This approach to inventory management improves overall operational efficiency and reduces costs.

Additionally, AI enables predictive maintenance of machinery and equipment, reducing downtime, ensuring continuity in the supply chain. This approach to proactive maintenance is exhausting reduce problems and build trust between supply chains.

Source Raw Materials

The integration of AI into supply chains and logistics is transforming the sourcing of raw materials or data center resources by streamlining processes and increasing productivity. A.I. Through predictive analytics, these systems can forecast demand to optimize inventory, and ensure timely procurement to meet manufacturing needs

AI also enables real-time monitoring of supplier performance, detecting deviations from expected standards of quality or supply. This approach reduces disruption and increases the resilience of the entire supply chain. Additionally, AI-powered automation streamlines the procurement process. It reduces manual errors and transaction costs associated with raw material acquisition.

Using AI technologies such as machine learning and natural language processing, organizations can gain valuable insights from data sources. Such as social media, news reports, industry reports etc. These data analytics subsequently helps identify emerging market trends, supplier risks and strategic sourcing partnership opportunities. Thereby competing for supply chain efficiency and sustainability and what it comes out of it.

Reduce Risk

Integration of AI in supply chain and logistics reduces risk. Through advanced analytics and scenario modeling, AI systems analyze multiple risks simultaneously. It enabling organizations to develop complex contingency plans and adapt risk mitigation strategies. For example, AI systems for manufacturing, inventory levels, customer orders and supply chains. The impact of chain of damage can be measured, allowing for more rapid response and effective mitigation strategies.

AI-powered supply chain monitoring tools continuously monitor identifying risks including supplier performance, demand changes, transportation delays and regulatory changes. This proactive assessment facilitates early detection of potential problems, and enables timely intervention , reducing the impact on performance.

Additionally, AI enables better supply chain visibility by providing both real-time tracking and inspection between supply chains. This transparency improves risk identification but also reinforces compliance, quality control and sustainability practice. It builds trust among stakeholders of the supply chain and ensures the resilience of the entire supply chain.

How Bigscal Technologies Can Help You To Integrate AI In Your Logistics Solutions

So, if you are searching for a software development company to leverage AI into your logistic business software then choose Bigscal Technologies. Wondering why? get your answer below;

At Bigscal, we integrate AI into logistics software seamlessly. First, we analyze company’s current systems and identify areas for improvement. Then, we develop AI-powered tools like predictive analytics to accurately forecast demand. This helps maintain inventory and reduce costs and supply chain planning.

We also use AI tools in optimizing processes, ensuring transportation is efficient and delivered on time. Machine learning algorithms are constantly learning from data to make better decisions, improving overall performance.

Additionally, we offer an AI-powered tracking system to manage shipments in real-time, enhancing security and reliability. This technology works seamlessly with your existing infrastructure, making the transition smooth and efficient.

Conclusion

The integration of artificial intelligence (AI) into supply chains and logistics is bringing a wave of change towards efficiency and innovation. From predictive analytics that transform inventory management to autonomous vehicles that facilitate transportation. AI is revolutionizing every aspect of the supply chain ecosystem. Hence, the benefits are undeniable.

FAQ

What are resilient supply chains?

A resilient supply chain is a robust, flexible system that can withstand disruptions such as natural disasters or economic fluctuations. It ensures that goods and services continue to be delivered to customers without significant disruption.

What are primary and secondary activities in supply chain management?

The Primary activities in supply chain management are key processes such as purchasing, manufacturing, and distribution. Secondary activities include supporting activities such as technical services, human resources and infrastructure.

What are value chains?

Value chains refer to the activities that add value from raw material acquisition to distribution, and focus on the processes and stakeholders involved in the creation and distribution of value

Give supply chain data analytics examples.

Examples of supply chain data analytics include demand forecasting using historical sales data, forecast maintenance. It is to optimize equipment performance, optimization methods for logistics efficiency, and supply chain risk analysis for strategic decision making.

How is generative AI used in supply chain management?

Generative AI in supply chain management generates synthetic data for training. Examples, creates scenarios for demand forecasting and optimization. It automates design processes, and improves decision making through scenario generation and analysis.

{

“@context”: “https://schema.org”,

“@type”: “FAQPage”,

“mainEntity”: [{

“@type”: “Question”,

“name”: “What are resilient supply chains?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “A resilient supply chain is a robust, flexible system that can withstand disruptions such as natural disasters or economic fluctuations. It ensures that goods and services continue to be delivered to customers without significant disruption.”

}

},{

“@type”: “Question”,

“name”: “What are primary and secondary activities in supply chain management?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “The Primary activities in supply chain management are key processes such as purchasing, manufacturing, and distribution. Secondary activities include supporting activities such as technical services, human resources and infrastructure.”

}

},{

“@type”: “Question”,

“name”: “What are value chains?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “Value chains refer to the activities that add value from raw material acquisition to distribution, and focus on the processes and stakeholders involved in the creation and distribution of value”

}

},{

“@type”: “Question”,

“name”: “Give supply chain data analytics examples.”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “Examples of supply chain data analytics include demand forecasting using historical sales data, forecast maintenance. It is to optimize equipment performance, optimization methods for logistics efficiency, and supply chain risk analysis for strategic decision making.”

}

},{

“@type”: “Question”,

“name”: “How is generative AI used in supply chain management?”,

“acceptedAnswer”: {

“@type”: “Answer”,

“text”: “Generative AI in supply chain management generates synthetic data for training. Examples, creates scenarios for demand forecasting and optimization. It automates design processes, and improves decision making through scenario generation and analysis.”

}

}]

}