The Role of Generative AI in The Logistic Industry

Quick Summary: Just like other industries, Generative AI is revolutionizing the logistics industry. It streamlining operations and optimizing processes. With its capabilities for accurate data generation, scenario mapping, and predictive demand. Generative AI enables more efficient route planning, inventory, warehouse management system, and resource allocation. Know more about how it can help you… By leveraging the power of AI enablement, logistics companies can compete in an ever-changing market environment.

Introduction

Generative Artificial Intelligence (AI) is emerging as a transformative force across industries, and the logistics industry is no exception. With the ability to generate data and innovation, generative AI technology is reshaping traditional logistics processes. It improves efficiency, accuracy and innovation.

At its core, the logistics industry revolves around the efficient and cost-effective management of goods and services flowing from origin to destination. Generative AI brings a unique capability to that landscape over this. It delivers solutions that optimize route planning, and warehouse management systems, demand forecasting and supply chain visibility. Companies in real-time at scale Analyze data. Which can unlock valuable insights to streamline operations and inform decision-making plans have been successful.

Additionally, generative artificial intelligence in logistics and supply chain, facilitates the creation of predictive models and simulations. This models empowering logistics providers to forecast and mitigate potential disruption before it occurs. From autonomous vehicles and drones outsourcing logistics operations to predictive maintenance and resource optimization, the application of generative AI in logistics is very promising and available.

In this article, we’ll explore the various ways generative AI is driving innovation and transforming the logistics industry, and ultimately shaping the future of global trade. The Logistics Software Development Company plays an important role in it.

What is Generative AI?

Generative AI refers to artificial intelligence that focuses on creating new objects. These objects are images, text, music, or even whole blocks of code, that mimic human creativity. Unlike traditional AI systems, which are programmed to, they will follow specific rules and guidelines. Generative AI models learn patterns and trends from large amounts of data and then develop new products based on those learned patterns.

One of the most prominent techniques used in generative AI is Generative Adversarial Networks (GANs). In it two neurons, a generator and a discriminator, are competitively pitted against each other.

Generative AI has huge applications in a variety of industries. It includes art generation, content creation, data enhancement, drug discovery. It also enables machines to express creativity and develop new products that can be used for purposes ranging from realistic painting to composition. To implement it in your industry Hire AI Developers.

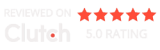

Types Of Logistic software

Before knowing more let’s first understand the types of Logistic software:

- Logistics management software solutions

- supply chain management System

- warehouse management software

- customer relationship management

- inventory management software

- shipment tracking System

- ERP software solution

- order management System

- Transportation management system

Read more: How To Develop A Transportation & Logistics Mobile App?

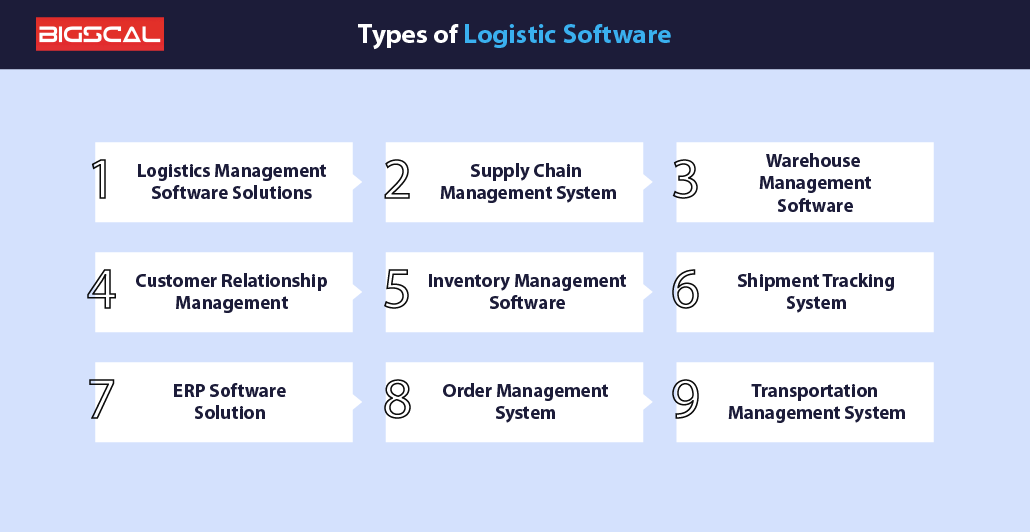

How Generative AI Transforming Logistic Industry

Here are the various ways by which Generative AI Transforming Logistic Industry, Let’s have a look:

Route Optimization

Generative AI is revolutionizing the logistics industry by optimizing route planning, right logistics management software and execution. Generative AI uses advanced algorithms and machine learning techniques. These techniques analyze large amounts of data including traffic, weather forecasts, historical classification data, and even driver behavior.

By integrating Generative AI Robotics into optimized route design, companies can dynamically adjust routes based on current conditions. It reduces delays, fuel consumption and overall operating costs. These systems ensure that effective and customer-centric strategies are used to ensure vehicle capacity, delivery time windows. You can also consider factors such as customer preferences.

Furthermore, generative AI enables continuous learning and adaptation. It enables efficiency algorithms to improve over time as they gather more data and refine their predictive capabilities. This iterative process provides a methodology for more accurate and efficient planning. Moreover, the productivity of the whole logistics management industry It also increases customers with a greater.

Demand Prediction

Generative AI is also transforming demand forecasting in the logistics sector. By analyzing historical sales data, market data, demographics, and other relevant factors. Generative AI algorithms can predict future demand with incredible accuracy.

These forecasts allow logistics companies to better monitor inventory. It ensures they have the right inventory in the right places at the right time. By accurately forecasting changes in demand, companies can reduce sales. Keep inventory control, reduce excess inventory costs, and improve the overall AI in supply chain.

In addition, Generative AI-powered demand forecasting systems facilitate active decision-making. It enables companies to adjust production schedules, allocate resources and optimize transportation routes in anticipation of changes in demand. This agility is critical in making and reacting to today’s fast-paced business environment.

Resource Allocation

The role of artificial intelligence in logistics is revolutionizing the logistics industry by a logistics management system optimizing resource allocation. It analyzes large amounts of data including historical data, real-time data, weather and traffic conditions and other external sources. AI algorithms can predict demand patterns and allocate resources such as cars, people and warehouses well and help.

Through advanced predictive models, generative AI helps logistics companies anticipate changes in demand and adjust their resource allocations accordingly. For example, during peak periods or special events, AI algorithms can dynamically allocate more inventory to high-demand locations or routes. It ensures on-time delivery and customer satisfaction when, at times of need learning, resources are reallocated to improve efficiency and reduce idle power.

By optimizing transportation management and resource allocation, powered AI enables logistics companies to be more efficient by reducing unnecessary resource consumption and emissions. Not unless this impacts resources not only benefits of ai in logistics the environment but also helps save costs and increase overall competitiveness in the industry.

Customized Delivery Solutions

Generative AI is reshaping thelogistics landscape by enabling distribution solutions personalized to individual customer needs. By analyzing vast amounts of data about customer preferences. Delivery locations and ordering habits. AI algorithms can automate delivery routes and fulfillment operations and optimize systems accordingly to work well and smoothly.

Generative AI, logistics companies can offer different delivery options to customers. It includes same-day delivery, fixed-time delivery, new delivery locations Leveraging predictive analytics. AI algorithms can predict which customers want and proactively suggest delivery options that match their needs and preferences.

Additionally, generative AI facilitates the delivery management and the development of new delivery methods such as drone delivery and autonomous vehicles. This technology allows for faster and more convenient delivery. Especially in urban areas where congestion and traffic congestion can test conventional delivery methods.

Risk Management

Generative AI is revolutionizing risk management in the logistics business by using advanced algorithms to predict and mitigate potential threats. By analyzing various external factors and integrating logistics management software such as historical data, real-time data, weather, and traffic conditions. Generative AI models can identify potential supply chain risks These risks include delays, road disruptions, inventory shortages, or even security threats.

Through predictive analytics, generative AI enables transportation and logistics and companies to quickly manage these risks. Thereby reducing their impact on operations and reducing costly disruptions. Always learning from the input of new data. These AI systems can adapt and refine their risk assessment models over time to increase their effectiveness in detecting and mitigating emerging threats.

In addition, generative AI facilitates the development of contextual models and simulation tools. It enables the transportation operations managers to analyze the probabilities of different risk scenarios and develop complex contingency plans as appropriate. By providing actionable insights and decision support. Generative AI empowers logistics companies to optimize their risk management strategy and increase overall business flexibility.

Load Optimization

Generative AI is transforming load optimization in the logistics industry by optimizing material distribution, efficiency, and reducing costs throughout the supply chain. By analyzing large amounts of data including product specification, demand dispatch, transportation constraints and demand forecasting. Generative AI algorithms intelligently assign loads and route freight Can determine route options.

These AI-driven optimization solutions can take into account various factors such as vehicle capacity, road distance, commute time, fuel consumption to create the best load schedule. It minimizes vacancies, reduces fuel as they control utilization and maximize availability by dynamically adjusting load allocation in real time based on changing conditions and demand models. Companies optimize their fleet performance It also enables save on significant costs.

Additionally, Generative AI facilitates planning and collaboration and provide benefits of artificial intelligence in supply chain management. It results in more efficient logistics and consumption of shared transportation resources efficiency and reduction.

Environmental Impact Reduction

Generative AI is transforming the logistics industry by autonomously designing routes and distributing resources. Thus, reducing fuel consumption and carbon emissions. Through advanced algorithms and predictive modeling. AI can analyze large amounts of data including traffic, weather and delivery schedules to determine the most efficient routes for logistics automotive industry. AI helps lower the carbon footprint of the logistics industry by reducing drift and unnecessary downtime.

Additionally, AI-powered predictive maintenance can prevent vehicle breakdowns and improve fleet management, reducing emissions from malfunctioning or poorly maintained vehicles. Furthermore, AI-powered supply chain management can optimize inventory levels. It reduces the need for faster shipping and reduced aircraft cargo. Which is a major driver of greenhouse gas emissions in the export of goods.

Automate warehouse operations

Generative AI streamlines warehouse operations by automating repetitive tasks such as inventory management, picking and replenishment. Using robotics’ machine learning algorithms, AI can optimize warehouse layouts, reduce travel distances for workers and robots, and increase inventory. This automation not only increases but decreases operational efficiency, employee costs and error risk as well.

Additionally, AI-powered predictive analytics can predict changes in demand and optimize inventory. It ensures that warehouses are stocking the right amount of inventory at the right time. This reduces the need for excess cargo excessively, potentially leading to waste, preventing wastage. It leads to delivery delays and potential customer dissatisfaction. Overall, AI-powered automation improves speed, accuracy and reliability in warehouse operations. Moreover, it improves the efficiency and competitiveness of logistics companies.

Supply Chain Management

Generative AI is transforming supply chain management by increasing efficiency, agility and transparency across the logistics chain. Using advanced algorithms and machine learning, AI-powered systems can analyze large amounts of data to optimize supply chains. These systems can accurately forecast demand, simplify inventory management, and improve resource allocation. For example, AI can predict demand patterns based on historical data, allowing companies to adjust production and inventory levels accordingly, reducing inventories and excess inventories.

Additionally, generative AI enables real-time tracking and monitoring of logistics, enabling companies to identify potential bottlenecks and delays. This approach enables greater responsiveness and reduces the risk of supply chain disruptions. Furthermore, AI-driven predictive analytics can identify potential risks and vulnerabilities. It enables companies to implement proactive risk management to mitigate supply chain disruptions.

Dynamic Pricing

Generative AI is also revolutionizing dynamic pricing strategies in the logistics industry. By analyzing a variety of factors such as real-time demand fluctuations, market trends, competitor pricing and consumer behavior. AI-driven systems can dynamically adjust prices to generate revenue and profits greater than.

These systems can determine optimal prices for products and services based on factors such as time of day, seasonality, and customer segmentation. For example, during periods of high demand or low productivity. AI algorithms can automatically raise prices to take advantage of market conditions. Conversely, prices can be adjusted downward during off-peak periods or to stimulate demand.

Additionally, Generative AI enables companies to personalize pricing strategies based on individual customer preferences and purchase history. It enhances customer loyalty and increases repeat business. By continuously analyzing data and adjusting pricing strategies as appropriate, companies can compete in the rapidly changing market environment.

Last Mile Delivery

Generative AI is revolutionizing the last-mile supply chain by optimizing routes, predicting demand and increasing productivity. By analyzing a wealth of data including historical delivery patterns, traffic conditions and customer preferences, AI algorithms can provide optimal delivery options in real time. This ensures delivery times are reduced, reducing fuel consumption and reducing operating costs for logistics companies.

Additionally, AI-powered delivery optimization enables businesses to offer more flexible delivery options, such as same-day or even same-hour delivery, meeting growing customer demand for convenience.

Furthermore, Generative AI can help provide tasks such as package sorting and loading, all automated by the last mile -Streamlines distribution system. Overall, by leveraging Generative AI, logistics companies can dramatically improve their last-mile delivery, resulting in faster, more accessible services to and cost-effective for businesses and consumers

Supply Chain Visibility

Generative AI in the supply chain increases supply chain visibility by providing real-time insights and predictive analytics. Through advanced algorithms, AI can analyze a variety of data sources, including inventories, supplier performance, logistic industry trends, weather or geopolitical events and the outdoors so new resources This comprehensive analysis enables companies to anticipate potential problems and proactively adjust their supply chain strategies to mitigate risk.

Additionally, Generative AI facilitates end-to-end visibility throughout the supply chain, enabling stakeholders to monitor the flow of goods from manufacturing to distribution centers and ultimately to the final customer. This transparency enables better decision-making, improved inventory management and enhanced collaboration with supply chain partners. By empowering AI technologies, businesses can achieve greater agility, flexibility and efficiency in their supply chain operations, ultimately delivering better customer experiences and gaining a competitive edge in the marketplace.

Read more: A Comprehensive Guide To Logistics App Development

Wanna Utilize Generative AI In Your Logistics Software? Approach Bigscal Technologies

If you want to implement Generative AI in your Logistic industry then approaching us can help you!

By integrating generative AI into our software solutions, we are changing how businesses manage their supply chains. Generative AI enables businesses to predict demand patterns, optimize route planning, and automate processes, ultimately leading to improvements in efficiency and cost savings.

Powered by our generative AI, logistics software analyzes large amounts of data in real time, enabling instant dynamic change. Whether adapting to unexpected interruptions or optimizing warehouse inventory, our system ensures a seamless operation and high resource utilization.

With our expertise in offering AI logistics solutions, we give businesses a competitive edge in today’s fast-paced marketplace. By working with Bigscal Technologies, companies can streamline, clean up their logistics processes operating costs to increase overall customer satisfaction.

Experience the future of logistics management with Bigscal Technologies. We transform your supply chain operations with the power of generative AI.

Conclusion

Generative AI holds a promise to transform the logistics industry. By generating real data, optimizing processes, and predicting demand, it streamlines operations, reduces costs, and improves efficiency. Furthermore, the ability to simulate different scenarios enhances decision-making and risk management. As technology continues to evolve, One must adopt the change, hence, integration of generative AI is one of the steps.

FAQ

What is third party logistics?

Third-party logistics (3PL) refers to the outsourcing of logistics services such as warehousing, transportation and distribution to specialized companies, allowing companies to focus on their core activities.

What is logistics software?

Logistics software is a digital tool that helps businesses manage and optimize their supply chain, including inventory management, logistics planning and warehouse optimization, to increase efficiency and reduce costs.

What system do logistics companies use?

Logistics companies typically use transportation management systems (TMS), warehouse management systems (WMS), and enterprise resource planning (ERP) systems to streamline operations, track shipments, track products and optimize logistics.

What is a logistics program?

A logistics system refers to a set of activities and processes designed to effectively manage products, information, and processes throughout the supply chain to better meet customer needs.

Who are logistics service providers?

Logistics service providers are companies that provide a range of logistics and supply chain services including transportation, warehousing, distribution, logistics and inventory management to businesses in various industries.